Harmel Academy of the Trades enlisted the help of Micron to build themselves a system from the ground up — the “Rat Patrol”.

The Rat Patrol is a system Micron created to keep our shop clean without an outside janitorial service. Within this system, we rotate cleaning tasks on a weekly basis. Every employee from machine operator to company president shares this responsibility for the cleanliness of the shop. Detailed work instructions guide us through the cleaning processes. And because every employee can participate, the workload on each of us is light.

This system caught the Harmel class’ attention when they toured Micron’s facilities. And when Harmel’s curriculum required students to build a system to address an existing need, they decided to use Micron’s Rat Patrol as the model for the creation of their own version.

Back to School

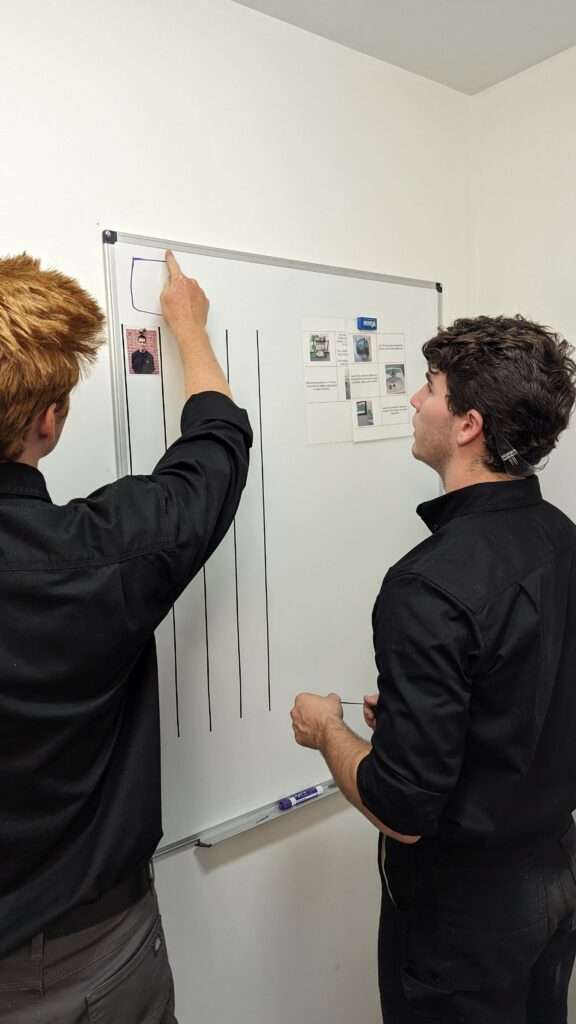

Micron’s continuous improvement expert, Dave Seabrook, spent a Friday morning with the students teaching the fundamentals of building such a system. Then the students put the lesson into action, working through the steps themselves.

First they set the goals and scope of the project. The group discussed the challenges they would need to overcome in achieving their goal. From there, the team assigned action items to complete the project.

They used 5S visual management to convert their current restroom to a well-organized area where every item in it had a purpose and housed all the items needed to perform a weekly cleaning. Then, they created work instructions for each task in the process and the visual systems needed to divvy up the responsibilities.

Each week, one member of the Harmel class cleans the restroom according to the rotating schedule and the work instructions they created. Then, the person scheduled to clean in the following week performs an audit to make sure the cleaning duties were completed. The end result is a robust system that will ensure the desired outcome — clean facilities.

Working with this group of young men and the Harmel program is always a pleasure, and we’re proud they identified our Rat Patrol system as one they wanted to model and recreate. We enjoy this employer-educator partnership immensely and look forward to working with Harmel again in the future.